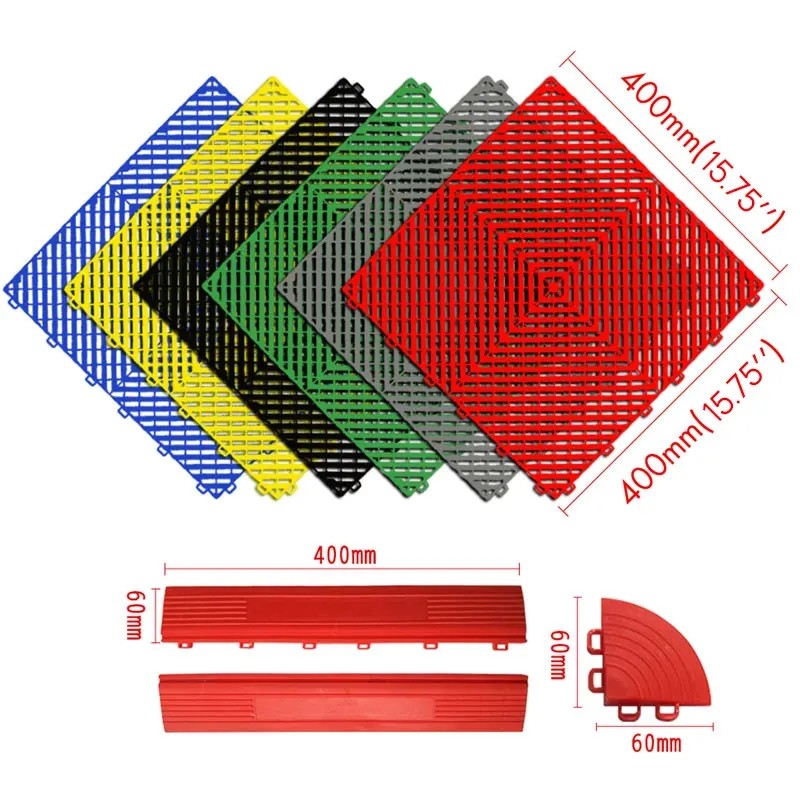

Product Size: 400*400*20mm 400*400*30mm 400*400*40mm 500*500*50mm

Load-bearing: 3-5 tons

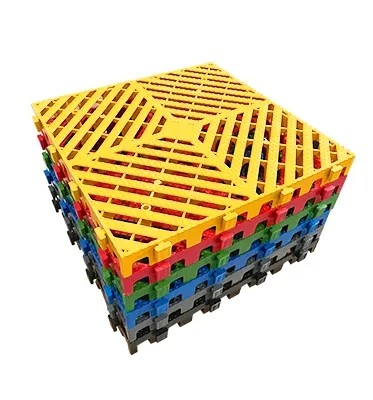

Structure:Stiffener bearing

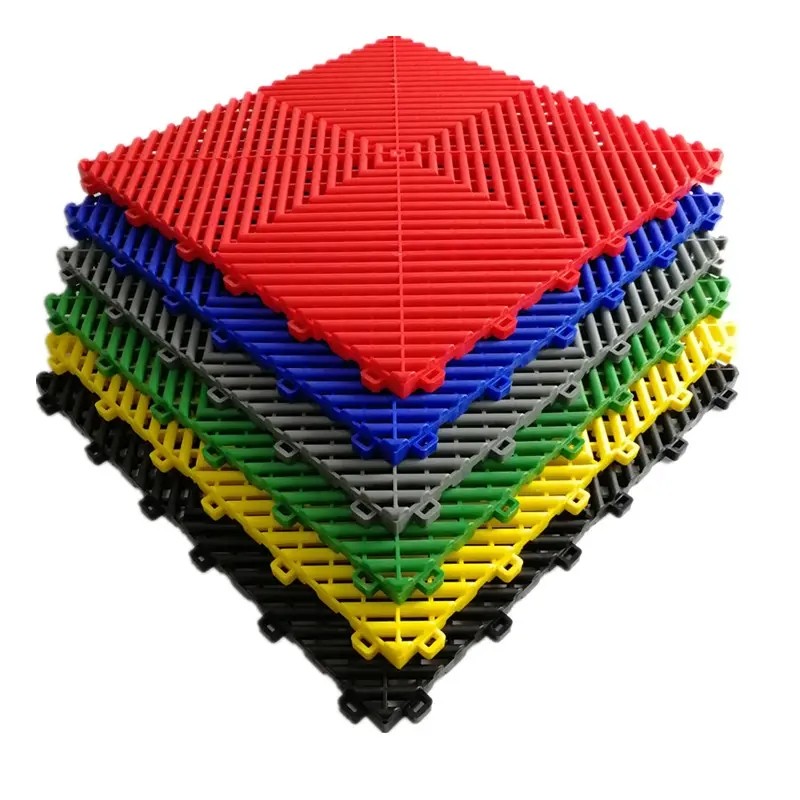

Color: Yellow, Black, Gray, Red, Blue,Green

Application scenarios: Car wash workshop, auto 4S store

Product advantages: pure raw materials, good toughness, wearresistance, light weight, easy installation